How inspect7® can be implemented for racking inspections?

All your inspections. All in one place. Our tagging system paired with our cloud-based portal creates the perfect digital solution for racking inspections. The inspect7® device attaches directly to the racking and is as quick and easy to use as paying with a contactless card.

Using our App, the inspector simply needs to tap an inspect7® device or label to start an inspection. Utilising one of our premade questionnaires, you can ensure that a thorough inspection is carried out on the racking system which meets all requirements. Inspection time scales can also be selected to match the requirements set out for that system. If you don’t like any of our premade questionnaires, no problem! Simply create your own to meet your needs.

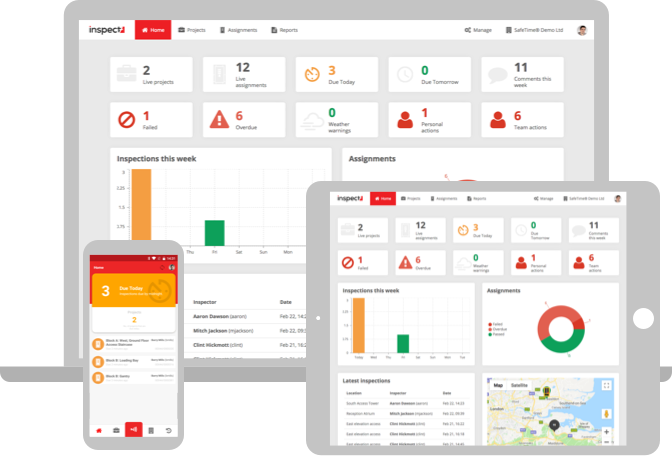

Using the online web portal, the PRRS or authorised user can instantly see the status of all the devices and can easily configure who can perform inspections by giving the PRRS the inspector role on your project. That way you have peace of mind that the correct people are doing the correct jobs.

The online web portal also allows the PRRS or anyone who has been granted access to instantly see the status of all the racking inspections. A visual dashboard provides key device data such as due, failed and overdue inspections to help prevent any oversight.

Using our task system, reporting issues or damage to the racking systems can be conducted by any member of staff given access to the project. They can either tap the device with the App or use the web portal to add a task. A title, description, images, required date and comments can all be added to the task. This can be assigned to the PRRS (or whoever else is required), our notification system will send the inspector a push (App) notification and/or email.

Tasks aren’t limited to just issues. Need more beams? Assign a task to the correct person. It’s simple to use our system for more than just inspections.

To find out more about how you can implement inspect7® into your business, book a free online demonstration.

Book a DemoHow do you assemble your racking? Access towers? We’ve got you covered their to in our next post…

Why does racking need Inspections?

Racking in warehouses or other industrial environments is classified as work equipment under the Health & Safety at Work Act (1974) and PUWER (Provision and Use of Work Equipment Regulations 1998). This stipulates that they must be maintained and inspected regularly.

Health & Safety Executive has a guide for Warehousing and Storage Systems called HSG76. This guide states why there is a need for inspections and the type of inspections needed for racking systems. These rules help ensure the working environments stay safe but also with increased uptime and a reduced risk of damaging stock.

HSG76 states that regular inspections should be carried out on racking due to regular use will cause damage, which will weaken the already lightweight materials of the racking.

The inspection intervals are determined after consideration of a variety of factors such as the frequency and method of operation, dimensions of the facility, equipment used and personnel involved which could all cause damage to the structure. These intervals should be determined by a nominated ‘Person Responsible for Racking Safety’ (PRRS) who is competent and able to complete these inspections after completing a sufficient training program like the rack awareness training by SEMA. HSE also states that these inspections should follow a hierarchical approach using several levels of inspection.

“The PRRS should ensure that inspections are made at weekly or other regular intervals based on risk assessment. A formal written record should be maintained.”

In section 645 of HGS76 under Visual inspections - Warehousing and storage: A guide to health and safety by HSE

The other type of inspection listed under this regulation is that an ‘Expert’ inspection should also be conducted.

“A technically competent person should carry out inspections at intervals of not more than 12 months. A written report should be submitted to the PRRS with observations and proposals for any action necessary."

In section 646 of HGS76 under ‘Expert’ inspections - Warehousing and storage: A guide to health and safety by HSE

Once an inspection procedure has been determined, then a damage or safety problem reporting procedure needs to be created. This is so that all employees of the facility can report damage and defects of the racking system immediately to the PRRS. Employees should also receive sufficient training on the racking systems they will be operating.

“Employees should receive training, information and instruction on the safe operation of the racking system, including the parts affecting their safety and the safety of others.”

In section 644 of HGS76 under Immediate responding - Warehousing and storage: A guide to health and safety by HSE

Please note this post is an example of how inspect7® can be implemented for inspection purposes only. All information in this post should not be taken as legal advice. Please refer to the Regulator’s documentation and manufacturers’ system specifications when introducing policies or making decisions regarding your business.